#Clinker Production

Explore tagged Tumblr posts

Text

Procedure of cement manufacturing in six simple steps

Cement is an essential building material that plays a crucial role in the construction industry. It is the binding agent used to create strong and durable structures. Wonder Cement Ltd is dedicated to providing high-quality cement to meet the diverse needs of the construction sector.

In this blog, we will take you through the six simple steps involved in the cement manufacturing process. We will shed light on cement manufacturing.

Step 1: Mining the Raw Materials:

The first step in cement manufacturing is the extraction of raw materials from the earth's crust. Limestone, clay, shale, iron ore, and other minerals are obtained through mining operations. These raw materials are carefully selected to ensure the desired chemical composition of the final cement product.

Step 2: Crushing and Pre-Homogenization:

Once raw materials are mined, they are transported to a crushing plant. Here, the rocks are crushed into smaller fragments to facilitate further processing. After crushing, the materials undergo pre-homogenization, where blending techniques are employed to ensure a consistent mix of raw materials. This step helps achieve the desired cement chemical composition and quality.

Step 3: Raw Material Grinding and Drying:

Crushed and pre-homogenized raw materials are then ground into fine powder in a raw mill. The grinding process utilizes rotating drums and steel balls to pulverize the materials. To prevent excessive moisture content, the powdered mixture is dried using hot gases before moving on to the next stage.

Step 4: Clinker Production:

In the clinker production stage, ground raw materials are fed into a high-temperature rotary kiln. The kiln operates at temperatures exceeding 1400 degrees Celsius, where materials undergo chemical transformation known as calcination. During this process, the raw materials are heated to the point where they form small, dark grey nodules called clinker.

Step 5: Cement Grinding:

The clinker is then finely ground with a small amount of gypsum in a cement mill. Gypsum is used to regulate cement setting time and enhance its properties. The grinding process transforms clinker and gypsum into a fine powder known as cement.

Step 6: Packaging and distribution

Once cement is produced, it is stored in silos before packaging. The final product is carefully packed in bags or loaded onto bulk transportation vehicles such as trucks or railcars. Proper packaging and handling ensure cement quality during transportation and storage. Wonder Cement Ltd maintains strict quality control measures to deliver a consistent and reliable product to its customers.

Cement manufacturing involves six simple steps, from mining raw materials to packaging. Wonder Cement Ltd follows these steps meticulously to produce high-quality cement for various construction needs. Understanding the cement manufacturing process provides valuable insights into the importance of each stage and the efforts required to ensure consistent quality. As a leading cement manufacturer, Wonder Cement Ltd remains committed to producing top-notch cement to contribute to the construction industry's growth and development. Their commitment to producing the finest quality cement is reflected in their use of state-of-the-art German machinery and innovative technologies like the ROBOTIC LAB. To learn more, click here.

#cement manufacturing process#mining the raw materials#Crushing and Pre-Homogenization#Raw Material Grinding and Drying#Clinker Production#Cement Grinding#Packaging and distribution#wonder cement

0 notes

Text

Cement Grinding Aids Market is driven by growing construction activities

The cement grinding aids market is crucial for optimizing the cement production process. Cement grinding aids help improve the grinding efficiency of finished cement. Grinding aids improve the grindability of cement clinker and reduce electricity consumption. Some key functions of cement grinding aids include enhancing grinding efficiency, improving powder flowability and rheology, reducing power consumption, and preventing agglomeration and coating of the grinded particles over the mill surfaces.

The Global Cement Grinding Aids Market is estimated to be valued at US$ 3336.4 Mn in 2024 and is expected to exhibit a CAGR of 8.1% over the forecast period 2024 to 2031. Key Takeaways Key players operating in the cement grinding aids market are Hiwin Corporation, Bosch Rexroth AG, The Timken Company, Schneeberger Group, Rockwell Automation Inc., Ewellix AB, THK Co. Ltd, Thomson Industries Inc., Parker Hannifin Corporation, Nippon Bearing Co. Ltd, HepcoMotion Inc., Lintech Corporation and NSK Ltd. The Cement Grinding Aids Market Growth is expected to witness strong growth in demand due to increasing construction activities across the globe. Rapid urbanization and infrastructure development projects are driving the demand for cement. Cement grinding aids help optimize cement production and meet the rising demand. Globally, the cement industry is expanding to new regions and countries. Growing construction activities in developing nations of Asia and Africa are contributing to the global cement demand. Key players in the cement grinding aids market are expanding their geographical footprint to leverage growth opportunities in emerging markets. Market key trends One of the major trends in the cement grinding aids market is the development of bio-based and environment-friendly grinding aid products. With growing environment concerns, cement producers are focusing on reducing carbon footprint and adopting sustainable manufacturing practices. Bio-based grinding aids help improve grinding efficiency as well as offer environmental benefits. These aids are derived from renewable plant sources and enable greener cement production. Their adoption is expected to rise significantly over the forecast period.

Porter's Analysis Threat of new entrants: The threat of new entrants is low due to high capital investment requirements and established presence of existing players. Bargaining power of buyers: The bargaining power of buyers is high due to availability of substitutes and presence of many regional players. Bargaining power of suppliers: The bargaining power of suppliers is moderate due to availability of substitutes. Threat of new substitutes: The threat of new substitutes is moderate due to availability of grinding aids from other industries. Competitive rivalry: The competitive rivalry is high due to presence of many regional players. Geographical Regions Currently, Asia Pacific region accounts for around 40% of the global cement grinding aids market value mainly due to high cement production and consumption in countries like China, India. The region will continue dominating the market during the forecast period due to rapid infrastructure development and urbanization. The fastest growing region for cement grinding aids market is expected to be Middle East & Africa region driven by ongoing and planned infrastructure projects across countries. The demand is projected to increase at a CAGR of over 10% until 2031 led by rising construction activities in GCC countries and investments towards community development in Africa.

Get more insights on Cement Grinding Aids Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Cement Grinding Aids Market#Cement Grinding Aids#Cement Additives#Grinding Aids#Cement Production#Clinker Grinding#Cement Processing#Cement Manufacturing#Chemical Additives#Milling Efficiency

0 notes

Text

This is a BIG DEAL.

Cement production is one of the biggest sources of CO2 emissions that doesn't directly involve burning fossil fuels. Sure, making cement uses a lot of energy, but theoretically that energy could come from renewable sources that don't emit CO2. Even if it did though, the process of making cement basically involves baking limestone until CO2 and water are driven out of it, creating a substance called "clinker" that is ground down into cement powder. So, making new cement from limestone always emits a lot of CO2, no matter what energy source you use.

This research basically showed that you can use old crushed up concrete waste in place of the flux that is usually used in smelting/recycling steel. Flux creates a glassy slag on top of the molten steel that captures impurities and protects the metal from oxygen while its molten hot. Using concrete as flux basically re-bakes the concrete back into clinker, which can then be used to create more cement and new concrete, while not producing any new CO2 emissions because you're basically baking the CO2 that reacted with the cement to make concrete back out of it. Its like how burning wood doesn't increase the total amount of CO2 in the atmosphere, because the carbon in the tree originally came from the air. Its only digging fossilized carbon out of the ground and adding it into the air that's the problem.

This is a huge step towards decarbonizing our building materials, and it doesn't involve any fancy new technologies, or speculative processes. This could be done today in steel mills that currently exist, they'd just have to switch flux sources and start saving the slag.

What a brilliant piece of industrial research!

15 notes

·

View notes

Note

There's good news on the climate impacts from steel! A Swedish company is working on replacing the coke (coal) with hydrogen, so that the only emission is water. Separately, another group has found that they can replace the limestone in steel arc furnaces with cement clinker that needs to be recycled, meaning that there's no CO2 emissions from turning raw limestone into clinker and old cement can be essentially "reacticated" and reused in concrete!

I am fucking ECSTATIC to hear this, it bodes really well for the continued future of body safe surgical steel as an implement for medical procedural tools and body modifications of both a medical and a recreational nature.

There's also a lot to be said for the resource redistribution opportunity that is public works projects, like for example, paying to have every steel manufacturer completely rennovate to meet the new sustainable/ethical model of production.

10 notes

·

View notes

Note

I’ve only known you for a short while, but in that time, you’ve made me belly laugh multiple times. I love your big squishy brain and listening to your ridiculous and serious ideas. 🐀

Now that we’ve gotten the sincerity out of that way - I would like you to name 3 facts about anything that tickle you. (Philosophy, history, stages of human decomposition, etc etc)

thank you! this means a lot to hear. its really kind of you to reach out. the asks were genuinely funny at first bc it felt so silly, but now im just : /

blood is like, weirdly good in concrete. it makes the concrete weather resistant (to an extent) bc the way the blood combines makes these little pockets of air. this is great bc it gives the concrete room to expand and shrink with weather changes. BUT i also hear it may make it brittle.

speaking of my beloved concrete, concrete/cement as it is mass produced today is unfortunately Not Good for the environment. its easy to use, durable, malleable, and theres ten billion cool things that can be done with it, but it uses a LOT of water and emits a LOT of co2. as in, 4-8% of the worlds co2 emissions are from concrete production. however, theres some really, really cool stuff being worked on to combat that! there are numerous less-co2-emitting kinds of concrete being invented. theres also carbon NEGATIVE concrete being made - concrete that during production takes co2 OUT of the atmosphere and traps it inside the concrete, making the sky a cleaner place and making the concrete tougher. also theyre making concrete with carrots.

speaking of both sustainability AND concrete. theres also self healing concrete. concrete that can heal itself (re: when stressors crack the concrete, the concrete "heals" itself and fixes the crack) means longer lasting, more durable concrete, which heavily cuts down on concrete production and keeps the air cleaner. some concrete heals when water is present bc of how it reacts to the clinker or carbonizes the lime. there are a few other ways, all of them cool, but my favorite is the addition of bacteria. bacteria in the concrete that, due to cracks, comes into contact with air/water, produces limestone and this fills in the cracks.

8 notes

·

View notes

Photo

Orkus - 2000

Thank to ramjohn for the scans!

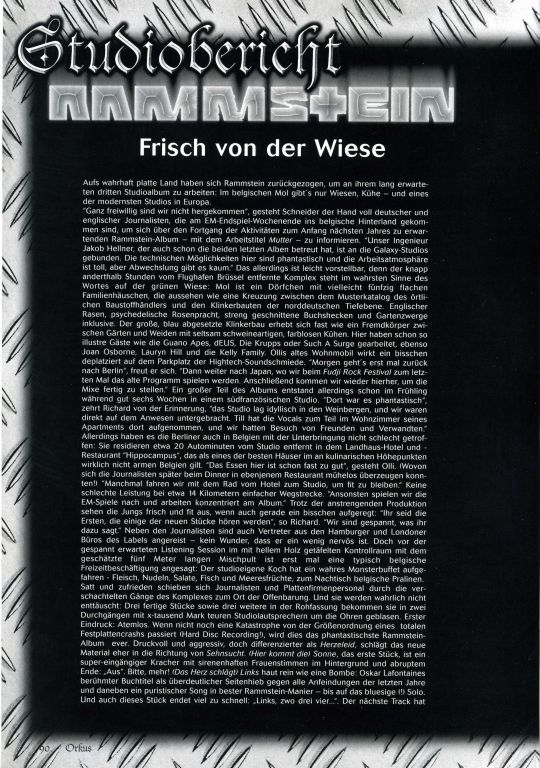

Rammstein have retreated to the truly flat country to work on their long-awaited third studio album: In Mol, Belgium, there are only meadows, cows — and one of the most modern studios in Europe.

"We didn't come here entirely voluntarily," Schneider admits to the handful of German and English journalists who came to the Belgian hinterland on the weekend of the EM final to find out about the progress of activities for the Rammstein album, working title ‘Mutter’, which is expected at the beginning of next year — to be informed. “Our engineer Jacob Hellner, who was also responsible for the last two albums, is tied to the Galaxy Studios. The technical possibilities here are fantastic and the working atmosphere is great, but there is hardly any variety.” But that's easy to imagine, because the complex, which is just under an hour and a half from Brussels Airport, is literally on a green field: Mol is a small village with maybe fifty low-rise family houses that look like a cross between the sample catalog of the local builders' merchant and the clinker brick building of the North German lowlands. English lawns, psychedelic splendor of roses, strictly trimmed boxwood and garden gnomes included. The large, blue clinker building rises almost like a foreign body between gardens and pastures with strangely pig-like, colorless cows. Illustrious guests like the Guano Apes, dEUS, Die Krupps or Such A Surge have worked here, as have Joan Osborne, Lauryn Hill and the Kelly Family. Olli's old mobile home seems a bit out of place in the parking lot of the high-tech sound company. “Tomorrow we're going back to Berlin,” he says happily. “Then on to Japan, where we will play the old program for the last time at the Fudji Rock Festival. Then we come back here to finish the mixes.” However, a large part of the album was created in the spring for a good six weeks in a studio in the south of France. "It was fantastic there," Richard recalls, "the studio was idyllically situated in the vineyards, and we were accommodated directly on the property. Till recorded part of the vocals in the living room of his apartment there and we had friends and relatives visiting.” Admittedly, the Berliners didn't do badly with the accommodation in Belgium either: They reside about 20 minutes by car from the studio in the country, house hotel and restaurant 'Hippocampus', which is one of the best in Belgium, which really has a lot of culinary highlights is applicable. "The food here is almost too good," admits Olli. (Which the journalists were able to easily convince themselves of later at dinner in the same restaurant!) “Sometimes we cycle from the hotel to the studio to stay fit.” Not a bad performance at around 14 kilometers one-way.

“Otherwise we replay the EM games and work concentrated on the album.” Despite the grueling production, the guys look fresh and fit, if just a little bit excited: “You're the first to hear some of the new tracks,” says Richard. “We are curious to see what you have to say about it.” In addition to the journalists, representatives from the label's Hamburg and London offices have also arrived — no wonder he's a little nervous. But before the eagerly awaited listening session in the light-wood paneled control room with the estimated five meter long mixing console, a typically Belgian pastime is the order of the day: the studio's own chef has set up a veritable monster buffet — meat, pasta, salads, fish and seafood, for dessert: Belgian chocolates. Fed up and satisfied, journalists and record company staff push their way through the complex's complex corridors to the place of revelation. And they certainly won't be disappointed: three finished pieces and three more in the raw version are blown around their ears in two rounds with studio loudspeakers costing x thousand marks. First impression: breathless. Barring another catastrophe of the magnitude of a total hard disk crash (Hard Disc Recording!), this will be the most fantastic Rammstein album ever. Powerful and aggressive, yet more differentiated than Herzeleid, the new material leans more in the direction of Sehnsucht. ‘Sonne’, the first track, is a super-catchy banger with siren-like female voices in the background and an abrupt end: «Aus». More please! ‘Links’ hits like a bomb: Oskar Lafontaine's famous book title as an obvious dig at all the hostilities of recent years and next to it a puristic song in the best Rammstein manner - except for the bluesy (!) solo. And this piece also ends far too quickly: 'Left, two three four...'. The next track also has a controversial subject: this is about a priest who feels attracted to his young protégés, in proper style with sacred choirs and bells. The three following rough mixes are announced as not yet finished, but they also promise something outstanding: ‘Mein Herz brennt’ is already very epic and reminds a bit of Puff Dandy's famous collaboration with Jimmy Page, here Till acts as a desperate children's fright. With a long, melancholic guitar solo and distinctive string riff, this might be the longest song presented. ‘Feuer frei’ seems the most electronic with its EBM rhythm, but impresses with ultra-fat riffs and crazy guitar effects. But this track also has a short, quiet middle part with noticeable synth sprinklings. "Bang Bang", the end - Rammstein seem to develop a preference for concise closing sentences on this album... Stylized children's babble marks the beginning of the most unusual and lyrically most personal of the songs presented: ‘Mutter’. Melancholic and balladesque, it comes across as a private reckoning with a traumatic, motherless childhood — less aggressive than deeply hurt. Although of course no savings were made on hearty lines of text.

After twice a good twenty minutes it's all over; Still a little dazed, but visibly enthusiastic, the crowd of critics staggers back to the surface. Predicate: particularly valuable — it would have to be hell if Rammstein weren't able to underpin their position as the most influential German band at the turn of the millennium with this album. Although there could still be a few surprises waiting for us between what we have just heard and the finished product: “We will be more varied,” promises Paul and grins, “the album should contain both punk influences and hits.” There still seems to be a lot to come!

#Rammstein#Till Lindemann#Paul Landers#Oliver Riedel#Christoph Schneider#Flake#Richard Kruspe#2000#*scans#*#that photo of Till ❤️

74 notes

·

View notes

Note

You may have already made a post about this so sorry if so, but what are your headcanons regarding how Matt and Katya met? And how they kept touch over the years?

Love your content btw!!

Thank you! And actually, somehow, no one has asked me that on any of the blogs! I had to think and coalesce some thoughts. This got long so I am going to split it into two parts but their meeting!

The Trans-Canada railway was completed in the 1880s and finally opened up what was called the ‘last best west.’ Between the Canadian Rockies in the far west and the western edge of the woodlands that define eastern Canada in Manitoba, the prairies stretch out in what looks to a child of the eastern woodlands like a vast treeless void. Grasslands and steppes are incredibly ecologically important, but I am ethnically a clinker-built canoe lover, and they scare the shit out of me. Judging by settlement patterns, most French Canadians agreed. As the American West closed, some Americans were willing to join Canadians and take land ripped from indigenous peoples too. Alberta was a result. Concerned about American settlement, in 1896, the Dominion of Canada’s federal government coordinated with the foreign office of the British Empire to look for more settlers. At the same time, in what was then the Austro-Hungarian empire, Galicia was likely the poorest place in continental Europe, with the only other comparable example being famine-era Ireland. The other Ukrainian-speaking areas of the Austro-Hungarian empire (75-80 of that territory was held by the Russian Empire) weren’t much better off. Each government found a solution in the other. Britain, representing Anglo-dominated Canada, and the Austrians shook hands, and the flow began. The US saw the largest share of Eastern European immigration in this period, but the majority who sailed to Canada were Ukrainians. And even before immigration, the region's international ties were based on Canadian financial interests. So, what does this mean for Katya and Matt?

The scene I imagine is that while the powerful wheel and deal, two products of empire crossed paths. One of these meetings may have taken place during a summer folk festival. Girls wove wreaths of flowers into their hair and floated others down the river. Songs were sung, vodka and wine flowed, and dancers joined hands. While the Austrians and the British bargained, a young man not so far removed from his peasant roots and his own saint’s day celebrated with fire and river wandered into the edge of a valley clearing at the end of the longest day of the northern year. As a maple or spruce was decorated, the sun sank, and the last light of day fell like fire light onto a Carpathian river valley. Bonfires were lit. Against a world on fire, a child of the woodlands looked upon the silhouette of his future, crowned with birchwood silver woven into her braids. Katya sensed him, a being like herself from across the world and turned. She looked at him a long moment, with eyes belonging to a world since passed set in the face that would one day be the image that sprang into Matthew’s mind when he needed to summon a memory of home that would not cleave him in two. She bid him to approach and, with one gesture, changed their fates.

Later, he would find out she spoke the court French of his earliest years, but this night, there is only Katya’s outstretched hand and burning blue eyes reflecting fire and Matt’s fingers lacing into hers to spin in the dance of all the other young men and women. There is no discussion of soil and wheat, nor opportunity and affection. There is only alcohol, laughter, music, fire and spinning, his mouth full of her language, unknown but already familiar. There is only a lightening of her eyes as she enjoys herself, her head flung back in laughter as he chokes on pear horilka stronger and sweeter than any whiskey he’s ever made. Her wreath topples out of her hair, and she bursts into laughter as he snatches it up and runs, calling over his shoulder, and she hikes up her skirts and follows, hand outstretched, only to grasp onto him and run, stride long and confident as they leap together to make it over the bonfire.

Still, together, hands clasped, his right her and left and left touching the laurel wreath, the last symbol she indulges from her Varangian roots. Eye contact, a significance, a weight that will one day balance the heaviness of history. She will press his heart into the shape of hers with that weight. He will give it back in every way he can, the ballast of whatever love she’ll let him give. But for now, in the last light of day, there is only a young man and a young woman hand in hand, circling a fire under a night sky. Here, they are under a star-streaked Milky Way that gives way to a mead moon rising over the mountains. Someday, save them; that moon will be the only witness to this night when mortality leaves alive only a man, a woman, and their most human memory.

#the ask box || probis pateo#canukr#katya || бо лишало на серці сліди#matthew || my country is winter#katya and matt || the soil of our souls#hws ukraine#hws canada

50 notes

·

View notes

Text

Harmony

HARMONY by Barry Manilow and Bruce Sussman directed by Warren Carlyle: It seems distressingly timely in the current political climate to see a musical about the real-life vocal group The Comedian Harmonists, who were suppressed by the Nazis in the early 1930s because half of them were Jewish (and in this production, two are gay or bi) and they performed Jewish music. It’s not that we don’t need to repeat history’s lessons about bigotry until none exists. It’s that the reflection of the play’s action in the current world can leave one a little shell-shocked. Fortunately, the play and production are worth it. Narrated by the incomparable Chip Zien as “Rabbi” Josef Roman Cycowski, the last of the group to die, the production deals with a great deal of regret as Zien looks back on the mistakes he made in dealing with the growing Nazi threat and, by extension, the guilt of people who stand by and do nothing while evil takes over a country. Zien is both funny (he plays a variety of other characters the group encounters) and intensely moving. As his younger self, Danny Kornfeld deserves particular credit for developing a character that really does look as if he could grow up to become the older actor. And Julie Benko is quite powerful as Ruth Stern, the anti-Fascist agitator who marries one of the group’s non-Jewish members. The dialog has the occasional clinker and there are some simplistic lyrics, but Barry Manilow’s score is a surprise. There’s only one number — the Josephine Baker fantasy “We’re Goin’ Loco!” — that mirrors his pop hits. For the rest, he moves effortlessly through a variety of musical styles, including the operetta “Your Son Is Becoming a Singer, the musical joke “Hungarian Rhapsody #20” (which would be great for a men’s chorus) and the beautiful anthem “Stars in the Night.”

16 notes

·

View notes

Text

Aside from water, concrete is the most-used material in the world, with about 14 billion cubic metres being used every year. Of that, 40% of that is used to build places for people to live.

If you were to pour that amount of concrete to make a paving slab ten centimetres thick, it would cover all of England and about half of Wales. In the US, the same amount would cover the state of New York.

But concrete production releases carbon dioxide (CO₂), one of the greenhouse gases that drives climate change. About 90% of emissions associated with concrete come from the production of Portland cement – this fine grey powder, the part that binds concrete ingredients together, was named after its resemblence to stone from the Isle of Portland, Dorset. Portland cement accounts for 7%-8% of the world’s direct CO₂ emissions.

Production of a more sustainable and cost-effective low-carbon cement, often nicknamed “green” cement, is scaling up. A new plant next to an existing cement plant in Redding, California, will produce about 15,000 tonnes of low-carbon cement every year. This could be used to make about 50,000 cubic metres of concrete, which is less than 0.0004% of the world’s concrete production.

At Redding, materials technology company Fortera turns CO₂ captured during conventional cement production into ready-to-use green cement, a form of calcium carbonate. This could reduce carbon emissions of cement by 70% on a tonne-for-tonne basis, according to Fortera.

A concrete issue

People have been using concrete for more than 2,000 years, by blending gravel, sand, cement, water and, sometimes, synthetic chemicals. It’s used to create everything from paths and bridges to buildings and pipes.

Currently, the EU uses more than two tonnes of concrete per person per year – 325kg of that is cement. That’s equivalent to the amount of food the average European person eats in five months.

Cement production is an energy-intensive process and the greenhouse gas emissions are hard to cut. When limestone is heated in a kiln, often fuelled by coal, nearly half that limestone is lost as CO₂ emissions.

This happens because limestone (calcium carbonate) breaks down in heat to form clinker, a mix of calcium oxide and CO₂. For every tonne of ordinary Portland cement made, 0.6-0.9 tonnes of CO₂ are released into the atmosphere.

So many industries rely on this material. The main challenge facing the cement industry is reducing CO₂ emissions at the same time as meeting global demand.

So as well as developing new technologies, low-carbon cement production must be established on a global scale to meet infrastructural needs required of economically developing nations.

Low-carbon alternatives

Other ways to reduce the carbon footprint of concrete include using fly ash (a by-product from burning coal in power plants) or slag (a by-product from steel production) to partially replace Portland cement.

However, sources of these materials will reduce as other industries decarbonise. Over time, less iron ore will be used to produce steel as more steel is produced from recycling existing steel, so there’ll be less available slag.

Current strategies for decarbonising cement and concrete rely heavily on using carbon capture and storage technology to capture unavoidable process emissions from cement plants.

So low-carbon cement production doesn’t have to involve replacing every cement production plant in operation. Low-carbon cement facilities can be retrofitted to capture CO₂ emissions released from manufacturing conventional cement. Plants can also use that captured CO₂ within the cement that they are producing or as a product for the food and chemical industries.

In Norway, Heidelberg Materials are building an industrial-scale carbon capture and storage plant at a cement facility that could capture and store an estimated 400,000 tonnes of CO₂ per year – that’s half the existing plant’s emissions.

However, this technology has a high investment cost for cement producers. Captured CO₂ can be stored underground, but this requires specific geological characteristics that aren’t guaranteed at cement production sites.

Greenhouse gas emissions in the cement sector are regulated by the EU’s emissions trading system. This was established to make polluters pay for their greenhouse gas emissions, reduce emissions and generate revenues to finance the green transition.

This legislation has not significantly reduced carbon emissions in the cement sector over the past decade, according to the International Energy Agency, mainly due to free emissions allowances being granted to cement manufacturers.

Despite sustained healthy profits in the cement industry, there hasn’t been enough investment in the widespread uptake of cleaner technologies and the sustainable use of materials. Greater financial incentives could help whereby companies have to pay for emissions associated with the production of cement.

As a design engineer, I appreciate that material choice and good design play a major role in the sustainability credentials of construction. Before low-carbon cement technology becomes more widespread, engineers, designers and builders can use construction materials more efficiently and choose products with lower embodied carbon – that’s carbon emissions released during the life cycle of building materials, from extraction through to disposal.

This approach could easily save 20% in embodied emissions associated with new building design.

Some governments could move towards only permitting the use of low-carbon cement. In Ireland, the Climate Action Plan 2024 requires that low-carbon construction methods and low-carbon cement are specified where possible for government-procured or government-supported construction projects.

Could all cement in the future be low-carbon or “green”? How “low-carbon” is defined will play a very important part in how this is translated into practice in the industry.

Retrofitting technology to large-scale existing cement production plants will prove that it’s technically possible to produce low-carbon cement efficiently at scale. With the right incentives in place by governments and the construction sector, almost all cement produced around the world could be low-carbon.

2 notes

·

View notes

Text

OCs as obscure references—bonus round lolll

ANIMAL: horse, elephant, falcon

COLOURS: gold, pale yellow, light blue, mustard green

MONTH: may

SONGS: it takes a muscle to fall in love, spectral display | because, the clinkers | jonathan, fiona apple | safer waters, chevelle | veslefrikk, karin krog | the suburbs, the arcade fire | roseate, ionna gika | eg veit i himmerik ei borg, helene bøksle

NUMBER: 3, 6, 8

PLANTS: grass, monstera

SMELLS: sweat, moist earth, chlorine, snow

GEMSTONE: amber

TIME OF DAY: noon

SEASON: early summer

PLACES: Hallingdal, Oslo, the jungle (DRC), hiking trails

FOOD: medisterkaker

DRINKS: beer, rum, akvavit

ELEMENT: earth; light

ASTROLOGICAL SIGNS: Taurus❂ Virgo❍ Scorpio↑ (apparently!)

SEASONINGS: dill, mustard, butter

SKY: blue with fluffy clouds

WEATHER: freezing day with brilliant sun

MAGICAL POWER: self-destruct

WEAPONS: M1921, bare hands

SOCIAL MEDIA: probably a stupid tumblr blog that makes no sense tbh

MAKEUP PRODUCT: (someone else's) lipstick

CANDY: kitkat

METHOD OF LONG DISTANCE TRAVEL: car that hopefully someone else is driving

ART STYLE: Stig Eklund

FEAR: failing his loved ones; weakness

MYTHOLOGICAL CREATURE: griffin

PIECE OF STATIONARY: lined paper

THREE EMOJIS: 😳💪🫡

CELESTIAL BODY: red dwarf

#roland#hes technically not an OC but#memecomradeoriginal#jungle work#thats one of kadokura's old colleagues btw for anyone who doesnt know#along with van owen and the rest. and if you get it im kissing you on the hand!! sensually

6 notes

·

View notes

Text

Optimizing Roll Press Performance in Cement Grinding

Since the commissioning in May 2007, Company A's cement pre-grinding system has faced frequent failures with the roll press. These issues include low and unstable working pressure on both sides, improper adjustment of the material distribution valve, large particle size of the material exiting the roll press, low hourly output, high grinding energy consumption, and poor overall economic efficiency. This article will share our experiences and improvement measures in controlling the roll press.

Problem Analysis and Solutions

1. Causes and Adjustments for Unstable Pressure

Material enters the roll press between the moving and fixed rollers through the upper feeding chute. We found that the material adjusting plate on the moving roller side extended toward the fixed roller. This caused the discharge point to shift toward the fixed roller. As a result, there was too much material on the fixed roller side and almost none on the moving roller side. This uneven distribution led to unstable pressure and ultimately resulted in large particle sizes in the output.

To solve this problem, in August 2010, Darko adjusted the material adjusting plate on the moving roller side. We moved its position from the fixed roller side to the outside of the moving roller. We also changed its angle from 45° to 60°. Additionally, we adjusted the initial roller gap to 10 mm. This allowed the material to flow properly between the rollers and distribute evenly, thereby controlling pressure fluctuations.

2. Causes and Adjustments for Low Working Pressure

After careful observation of the roll press and hydraulic system, we found that the initial pressure on both sides of the system was 6.0 MPa. The equipment could only start when the pressure was loaded to 5.5 to 6.5 MPa. The operators typically increased the pressure to 6.0 MPa and then stopped. Due to the limitations of the initial roller gap, the oil pressure in the hydraulic cylinder was insufficient at 6.0 MPa. Even if the roller gap increased, the pressure could not reach the working pressure of 8.2 MPa.

We realized that the initial pressure had a significant impact on the working pressure. Therefore, we adjusted the initial pressure to 6.5 MPa while stabilizing the material flow at the inlet. After this adjustment, the working pressure on both sides increased from 7.4 to 7.8 MPa to 8.2 to 8.6 MPa, resulting in a noticeable reduction in particle size.

3. Adjusting the Material Distribution Valve

During the grinding process, the material forms a cake and discharges from the lower part between the two rollers. With sufficient feeding, the material is effectively pressed. However, the pressing effect on the edge material is not as good as that on the center material. The role of the material distribution valve is to separate well-pressed material from poorly pressed material.

We mistakenly believed that a smaller opening of the distribution valve was better and adjusted it to 20%. As a result, the finished product contained coarse material around 10 mm. Upon inspecting the side door of the roll press, we found significant material buildup in the edge chute, which hindered smooth flow. After making further adjustments, we discovered that setting the distribution valve opening to 23% eliminated the material buildup, allowing smooth entry into the return belt.

Conclusion

Through these measures, we successfully reduced the average particle size of the clinker from the roll press from 3.81 mm to 1.54 mm. The crushing ratio improved from 4.09 to 10.10. The appearance of the ground material became powdery, and most particles could be easily crushed by hand. Additionally, the hourly output of the ball mill increased by 13.1%, and the system's grinding energy consumption decreased by 16.6%. These improvements significantly enhanced the system's economic efficiency and operational stability. If you face similar issues, please feel free to contact us. We are happy to help!

0 notes

Text

Andhra Cements Rights Issue Date, Price, Market Lot, Subscription 2024

Andhra Cements Rights Issue dates are not finalized. Andhra Cements primarily manufactures and markets various types of cement products. The main products include Ordinary Portland Cement (OPC) and Portland Pozzolana Cement (PPC), both produced at their manufacturing plants in Dachepalli and Visakhapatnam, Andhra Pradesh. The company also produces clinker, which is a key intermediate product in…

0 notes

Text

Supplier of Stainless Steel Black Bar in West Bengal

Arisa Impex is a prominent Manufacturer and Supplier of Stainless Steel Black Bar in West Bengal. We are located in Ahmedabad, Gujarat, India. Arisa Impex offers a wide range of dryers for various industrial applications, including drying of minerals, chemicals, and more. The black finish provides a sleek, modern look, making these bars suitable for both functional and decorative applications. Features of Our Rotary Dryer Plants: High Drying Efficiency: Achieve rapid and efficient drying with minimal energy consumption. Robust Construction: Built with high-quality materials and components for long-term durability. Easy Maintenance: Designed for easy access and maintenance, minimizing downtime. Customizable Designs: Tailored to meet specific process requirements and material characteristics. Advanced Controls: Equipped with advanced control systems for precise temperature and moisture control. Specification: Finish: Bright, Polish & Black Diameter: 25mm to 152mm Range: 3.17 MM TO 350 MM DIA Length: 1 to 6 Meters, Custom Cut Lengths Condition: Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished Form: Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wiremesh, Billet, Ingot, Forging Etc., Industries We Serve: Mining: Minerals, Ores, Concentrates Chemical: Chemicals, Fertilizers, Pharmaceuticals Food Processing: Grains, Vegetables, Dairy Products Cement Industry: Raw Materials, Clinker Pharmaceutical Industry: APIs, Intermediates What kind of after-sales support do you offer? We provide comprehensive after-sales support, including installation, commissioning, operator training, and ongoing maintenance services to ensure smooth and uninterrupted operation. How can I get a personalized quote for my drying needs? Contact us today for a free consultation. Our experts will assess your specific requirements and provide you with a customized quote and a detailed project proposal. Arisa Impex is a Supplier of Stainless Steel Black Bar in West Bengal including locations like Kolkata, Asansol, Siliguri, Durgapur, Bardhaman, Malda, Baharampur, Habra, Kharagpur, Shantipur, Dankuni, Dhulian, Ranaghat, Haldia, Raiganj, Krishnanagar, Nabadwip, Medinipur, Jalpaiguri, Balurghat, Basirhat, Bankura, Chakdaha, Darjeeling, Alipurduar, Purulia, Jangipur, Bolpur, Bangaon. Contact us today to discuss your requirements or request a quote. View Product: Click Here Read the full article

0 notes

Text

🧱 सीमेंट कैसे बनता है | Cement Making Process 2024 | Construction Tips 🔧

🧱 सीमेंट कैसे बनता है | Cement Making Process 2024 | Construction Tips 🔧 🧱 सीमेंट कैसे बनता है? जानें इस वीडियो में Cement Making Process 2024! इसमें आपको raw materials, clinker, और final product के बारे में जानकारी मिलेगी। Cement का इस्तेमाल कैसे होता है और इसकी quality कैसे maintain की जाती है, यह सब हम आपको बताएंगे। इस वीडियो को ज़रूर देखें अगर आपको construction और building tips में interest…

0 notes

Text

Cement Industry, From Carbon-Intensive to Carbon-Neutral

As the world steps up its efforts to combat climate change, industries contributing significantly to global greenhouse gas (GHG) emissions, unlike cement, face immense pressure to transition toward sustainability. Responsible for about 8% of global CO2 emissions, the cement industry is at the forefront of this transformation. While cement production remains essential for modern infrastructure, the challenge now is to find greener ways of producing it. As a response, the sector is embarking on a Net Zero pathway, aiming for a 25% reduction in CO2 emissions by 2030 and a full decarbonization by 2050, driven by technological innovations, use of alternative raw materials, and circular economy principles. This path is reshaping the cement industry, making it more sustainable while continuing to meet global infrastructure demands.

One of the most effective strategies has been the adoption of alternative raw materials. Traditionally, cement production relies heavily on limestone, contributing significantly to emissions. However, by integrating clinker substitutes such as fly ash, Ground Granulated Blast Furnace Slag(GGBFS), and calcined clay, the industry has reduced its CO2 footprint. These materials, sourced from industrial waste like coal power plants and steel production, fit within the framework of the circular economy. Not only do they help minimize new resource consumption, but they also reduce the overall environmental impact of cement manufacturing. This shift toward alternative materials is particularly visible in the ready-mix concrete (RMC) sector. Here, eco-friendly materials like fly ash and GGBFS are increasingly being adopted, ensuring that these solutions align with the industry’s sustainability objectives without compromising on performance.

Through these innovations, companies are leading the charge toward a greener future while maintaining high-quality standards.

Energy consumption has long been a significant challenge for the cement industry, with production being highly energy-intensive. Traditionally reliant on fossil fuels such as coal, the industry is now rapidly transitioning to renewable energy sources like solar and wind. Additionally, alternative fuels such as biomass, municipal waste, and used tires are gaining traction, further reducing dependence on fossil fuels and lowering overall emissions. Within the broader concrete production sector, similar strides are being made to incorporate renewable energy into operations. These changes highlight the cement industry’s ongoing efforts to reduce its environmental impact while maintaining operational efficiency.

Energy optimization is another critical area of focus. Technologies such as waste heat recovery systems, which convert excess heat from the production process into electricity, have proven highly effective. Moreover, the adoption of pre-calciners and pre-heaters has drastically improved the thermal efficiency of clinker production, cutting down on energy consumption during the most energy-intensive phase of cement manufacturing. These technological innovations are driving significant improvements in energy efficiency, not just in cement production but across the construction materials industry as a whole.

The transport of cement and related materials also accounts for a significant share of industry emissions. Diesel-powered trucks are still widely used, but the shift toward greener options, such as rail and waterway transportation, is gaining momentum. Some manufacturers are also investing in more eco-friendly vehicle fleets powered by compressed natural gas (CNG) and electric engines, further reducing emissions within the supply chain. Water conservation is emerging as another important focus area for the cement sector. Cement production has traditionally been a water intensive process, but with growing concerns around water scarcity, manufacturers are adopting technologies like rainwater harvesting, air-cooled condensers, and water recycling systems to reduce usage and promote sustainability across their operations.

Another area showing promise is digitalization. Through advanced data analytics and automation, manufacturers can monitor real-time data on energy usage, emissions, and resource consumption. This allows for quick, efficient adjustments to production processes, optimizing efficiency and minimizing waste. The construction sector, particularly ready-Mix concrete plays a critical role in supporting the cement industry’s sustainability efforts.

By integrating advanced technologies and adopting green strategies, these companies contribute to the overall industry’s Net Zero ambitions and a sustainable future. While the road to reducing cement industry emissions presents numerous challenges, the opportunities for innovation and collaboration are immense. With ongoing technological advancements, policy support, and a commitment from across the sector, the cement industry is well-positioned to lead the journey toward a Net Zero future.

Visit our site to know more : https://www.aparnaenterprisesltd.com/

0 notes

Text

Synthetic Gypsum Market: A Growing Alternative with Sustainable Potential

In recent years, the synthetic gypsum market has witnessed a substantial rise, largely propelled by industries that value sustainable, cost-effective alternatives to natural resources. Synthetic gypsum, produced as a byproduct from various industrial processes, has carved out a vital role across sectors like cement production, building materials, gypsum board manufacturing, soil amendments, and even dentistry. This market trend is not just about substituting natural gypsum but also about supporting industries with a more environmentally friendly and accessible option.

Synthetic gypsum market size is projected to grow from USD 1.4 billion in 2024 and is projected to reach USD 1.8 billion by 2030, at a CAGR of 4.3%.

Let’s delve into the unique dynamics and potential of synthetic gypsum, highlighting its applications, challenges, and emerging opportunities for industries that are increasingly focused on sustainable growth.

What is Synthetic Gypsum?

Synthetic gypsum is chemically identical to natural gypsum—both composed of calcium sulfate dihydrate. However, unlike natural gypsum that is mined, synthetic gypsum is a byproduct, often generated from industrial processes like flue gas desulfurization (FGD) in coal-fired power plants. When these plants capture sulfur dioxide emissions to reduce air pollution, the process yields synthetic gypsum as a usable byproduct. This environmentally beneficial cycle transforms waste into a resource, aligning with broader sustainability goals.

This "upcycled" form of gypsum can be used almost interchangeably with natural gypsum in many applications, thus reducing the demand for mining activities and conserving natural resources.

Key Factors Driving Market Growth

Sustainable Construction and Building Materials: In today’s world, there’s a growing demand for greener building solutions. Since synthetic gypsum comes from recycled industrial byproducts, it’s an attractive option in the construction industry. It conserves natural gypsum reserves, reduces waste, and helps minimize environmental damage, making it an ideal choice for eco-conscious builders and contractors.

Increasing Regulatory Focus on Environmental Protection: Environmental regulations around air quality have driven more facilities to adopt FGD systems, inadvertently boosting synthetic gypsum supply. Governments worldwide have implemented strict environmental policies to reduce industrial emissions, further encouraging the use of synthetic gypsum. The fact that this byproduct can be reused in critical industries only strengthens its appeal.

Surge in Demand for Gypsum Board: The construction boom, particularly in urbanized and rapidly developing regions, has led to an increased demand for drywall. Synthetic gypsum plays a critical role in gypsum board production, offering a fire-resistant, durable, and easy-to-install building material that is highly valued in the construction industry. With this demand on the rise, synthetic gypsum is increasingly essential to meet production needs.

Growing Agricultural Applications: Agriculture is an emerging avenue for synthetic gypsum, where it acts as a soil conditioner. Gypsum helps improve soil structure, enhance water absorption, and prevent erosion. This application has gained attention worldwide, especially in arid and semi-arid regions where synthetic gypsum can provide essential nutrients like calcium and sulfur, improving crop yield and soil health.

Dental and Medical Fields: While perhaps less known, synthetic gypsum is also used in dentistry to create molds and impressions. Its uniformity and purity make it a great choice for this precision-driven field. This niche application is opening up new avenues for synthetic gypsum, as dental professionals recognize its benefits over traditional materials.

Key Applications of Synthetic Gypsum

Cement Production: In cement production, synthetic gypsum is added to clinker to control the setting time. This not only helps improve the consistency of cement but also enhances its structural properties. With synthetic gypsum as an alternative, cement producers can opt for a sustainable and cost-efficient material, supporting their production processes without compromising quality.

Gypsum Board (Drywall) Manufacturing: Synthetic gypsum has a pivotal role in gypsum board manufacturing, particularly in regions like North America and Europe. Gypsum board, made of a gypsum core sandwiched between paper liners, is essential for interior construction. It offers fire resistance, ease of use, and cost-effectiveness. As construction activities increase globally, especially with new housing and commercial projects, synthetic gypsum's demand is set to grow significantly in this segment.

Soil Conditioner in Agriculture: For agricultural use, synthetic gypsum has shown promise as an effective soil amendment. It can improve soil quality by adding calcium and sulfur, enhancing root growth, and aiding in water absorption. This is particularly beneficial in saline or sodic soils, where gypsum helps to balance the soil structure, allowing for better crop growth and soil health.

Dental and Medical Uses: In the dental industry, synthetic gypsum is highly valued for its use in creating dental molds, impressions, and casts. Due to its chemical consistency and purity, synthetic gypsum is a preferred choice in this field, meeting the precision requirements necessary for high-quality dental applications.

Challenges and Future Opportunities

While synthetic gypsum holds numerous advantages, the market does face a few challenges. Transportation costs can be high due to the weight and bulk of gypsum, which may limit its usage in areas far from production facilities. Quality control is another consideration, as synthetic gypsum derived from different sources can vary, making consistent standards necessary, especially for high-end uses in industries like construction and healthcare.

However, the future looks bright for synthetic gypsum. As sustainable materials gain popularity and industries continue to prioritize recycled content, synthetic gypsum is well-positioned to meet the growing demand. Emerging markets, in particular, offer significant potential as they expand infrastructure and prioritize environmentally friendly resources. Additionally, advancements in synthetic gypsum production processes could further enhance its quality, expanding its application potential across new sectors.

To know more Download PDF Brochure :

The synthetic gypsum market is more than just a substitute for natural gypsum—it’s a sustainable alternative that holds unique value across multiple industries. By repurposing industrial waste, synthetic gypsum helps conserve natural resources, supports sustainable manufacturing practices, and meets the needs of diverse applications. From construction and agriculture to healthcare, synthetic gypsum is making a positive environmental impact, helping industries reduce their carbon footprint and promote greener practices. As industries continue to move towards sustainability, synthetic gypsum’s role is only set to grow, carving a more substantial presence in the global marketplace and contributing to a greener future.

#Synthetic Gypsum Market#Sustainability#Cement Industry#Building Materials#Gypsum Board#Soil Amendments#Eco-Friendly Solutions

0 notes